Unleashing the power of automation and exploring the benefits in the manufacturing sector

In today’s competitive business landscape, the manufacturing sector constantly seeks ways to improve efficiency, reduce costs, and enhance productivity. Automation has emerged as a transformative force, revolutionizing the industry and paving the way for significant advancements. Automation streamlines operations increases efficiency, and boosts output by harnessing cutting-edge technologies. Quality control is improved through precise and consistent processes, while cost reduction and resource optimization are achieved by minimizing waste and maximizing resource utilization. Workplace safety is enhanced, leading to higher employee satisfaction. The adaptability and scalability of automation enable manufacturers to respond promptly to market demands and stay ahead of the competition.

Furthermore, automation drives innovation and technological advancements, pushing the boundaries of what is possible in manufacturing. Manufacturers must embrace automation as a strategic imperative to thrive in this evolving landscape.

Streamlining Operations and Increasing Efficiency

Automation in the manufacturing sector has proven to be a game-changer in streamlining operations and enhancing overall efficiency. By replacing manual labor with automated systems, companies can minimize human error, improve accuracy, and optimize production processes. Tasks previously time-consuming and prone to mistakes can now be performed swiftly and accurately by machines, allowing employees to focus on more complex and value-added activities.

Enhanced Productivity and Output

With automation, manufacturing companies can achieve unparalleled levels of productivity and output. Automated systems can operate 24/7 without breaking, resulting in continuous production cycles. Furthermore, machines can perform repetitive tasks significantly faster than humans, resulting in increased output and shorter lead times. This improves customer satisfaction and enables businesses to meet growing demands efficiently.

Improved Quality Control and Consistency

Quality control is of utmost importance in the manufacturing sector. Automation plays a critical role in ensuring consistent and high-quality products. By leveraging advanced sensors, artificial intelligence, and machine learning algorithms, automated systems can detect defects, monitor production parameters, and make real-time adjustments to maintain optimal quality standards. This level of precision and consistency minimizes the likelihood of errors and helps businesses deliver products that meet or exceed customer expectations.

Cost Reduction and Resource Optimization

Another significant advantage of automation in the manufacturing sector is cost reduction. While initial investments in automation technology may be substantial, the long-term benefits far outweigh the expenses. Automated systems reduce the need for manual labor, leading to significant savings in labor costs. Moreover, by optimizing processes and minimizing waste, businesses can reduce material costs and maximize resource utilization. Automation also decreases the likelihood of rework, reducing the expenses associated with product defects.

Workplace Safety and Employee Satisfaction

Automation benefits businesses, improve workplace safety and enhances employee satisfaction. Companies can protect their workforce from potential injuries and health risks by automating hazardous or physically demanding tasks. This creates a safer work environment and boosts employee morale. Additionally, automation frees employees from monotonous and repetitive tasks, allowing them to focus on more engaging and intellectually stimulating work. This, in turn, enhances job satisfaction and employee retention.

Agile Adaptability and Scalability

Adapting quickly and scaling operations is crucial for success in today’s dynamic business environment. Automation empowers manufacturing companies to be more agile and responsive to changing market demands. Automated systems can be easily reprogrammed and reconfigured to accommodate new product designs or process changes. This flexibility allows businesses to introduce new products faster, respond to customer demands promptly, and stay ahead of the competition.

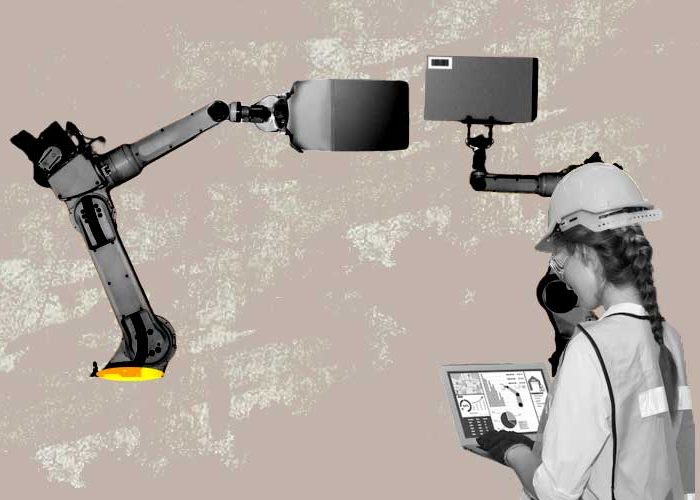

Innovation and Technological Advancements

Automation integration in manufacturing has paved the way for innovation and technological advancements. By embracing automation, companies can leverage emerging technologies such as the Internet of Things (IoT), artificial intelligence, robotics, and big data analytics. These technologies enable the collection and analysis of vast data, providing valuable insights for process optimization, predictive maintenance, and intelligent decision-making. Automation catalyzes technological progress, driving innovation and pushing the boundaries of what is possible in manufacturing.